Hi, I’m Joseph

I’m a 3D printing enthusiast, audiophile snob, web programmer,

and full-time tinkerer.

Tech-savvy dude that would willfully fix printers!? Whaaaaaa?

Whenever people asked me if I, a programmer, could fix their jammed ink-jet printer, I would ask them this: just because someone can play the piano doesn’t mean they could fix or tune a piano right?

Fast forward through a decade in my career, and about a month ago, the teacher of my daughter asked me to help with setting up Bambu A1 Mini, and I was hooked. After some research, learning more about Klipper and Voron, I hit the buy button on an LDO 2.4 kit on Taobao from China, that’s still on it’s way. I also got this Sovol Zero for printing parts for the Voron, prototyping, getting familiar with Orca Slicer, and to make sure I’ll always have at least one functional printer.

Below is the result of my work so far.

Portfolio

I do my best to print only things that I would use that will not sit in a pile of fidget toys. After printing the first Voron cube, the very next thing I did was went through all the calibrations for ASA. Nozzle temp, flow ratio, max volumetric flow rate, input shaping and adaptive advance pressure. Here are the few prints that I’ve done. The first two I designed on Fusion360. I learned the software a few years back when I created a one-off CNC keyboard.

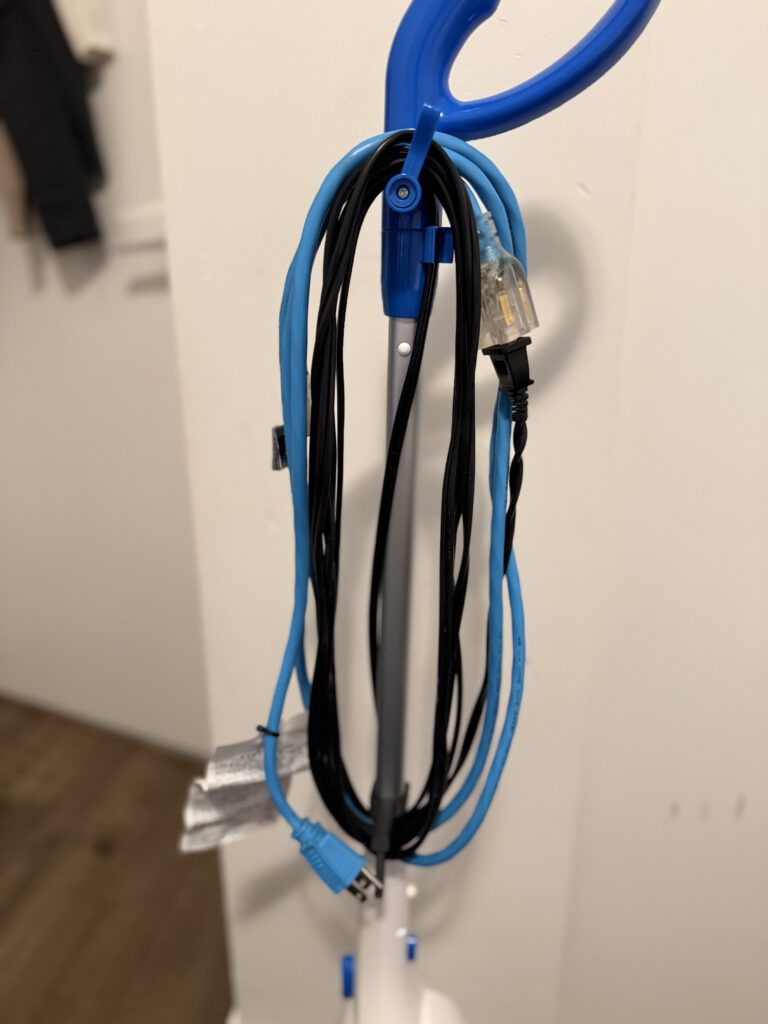

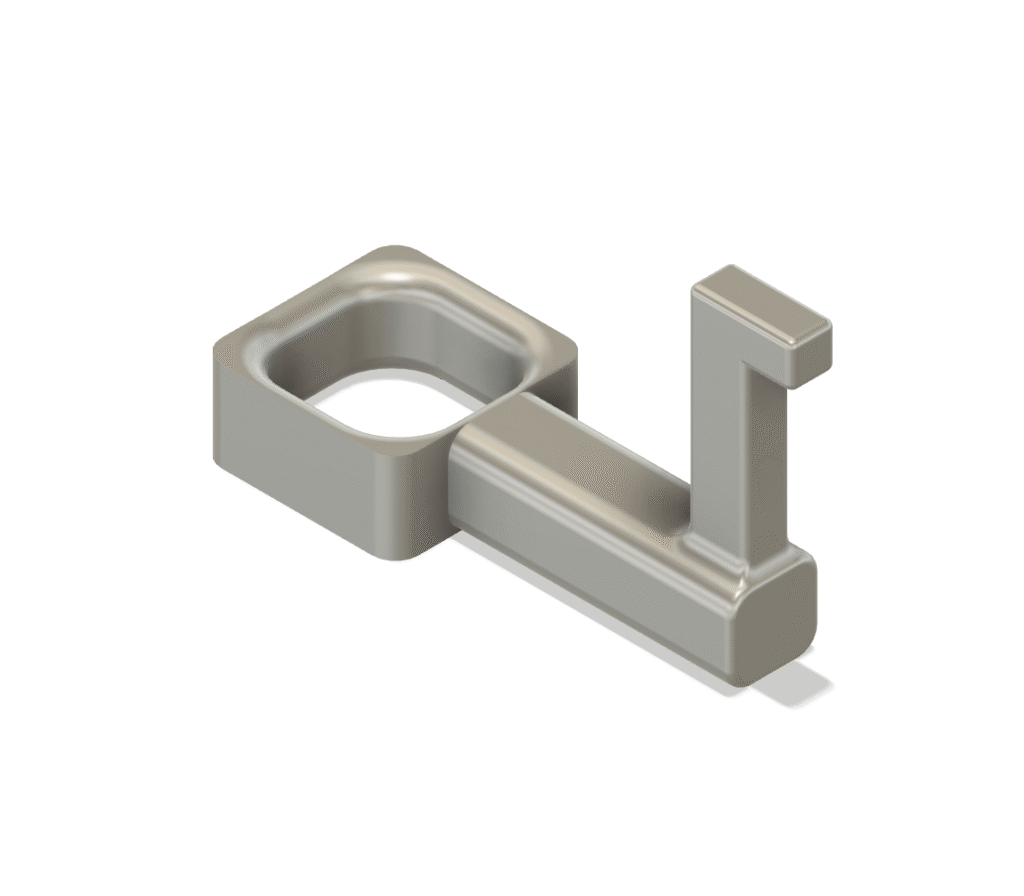

Cable hook

The first problem I fixed was a broken cable holder on my steam broom since there is no replacement part for such a budget unit. I tested the fit a few times until I found a profile that would fit in without breaking the part.

Cup holder insert

This is a minor pain point where a smaller bottle would slosh around in the cup holder, so I made modeled an insert and some TPU clips to go with it. Still WIP since some bigger bottles wouldn’t work, so I’ll have to redesign and widen the lip of the insert. Please note that the TPU profile I still hasn’t been completely dialed in and the pic is just shown here for demonstration purposes.

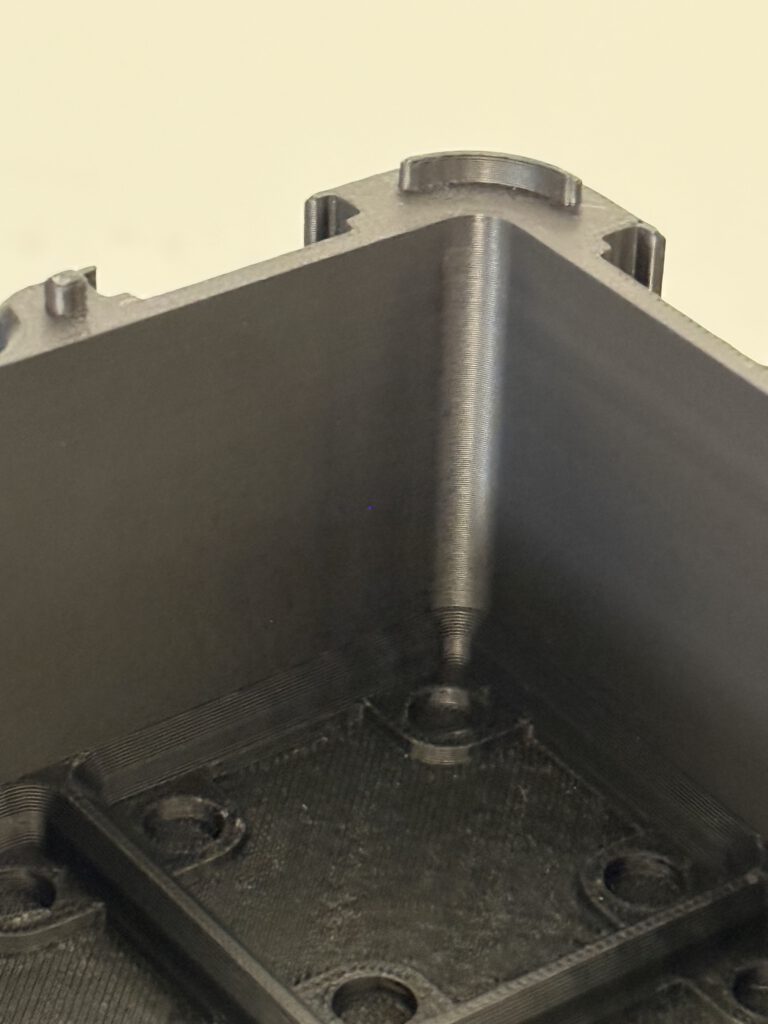

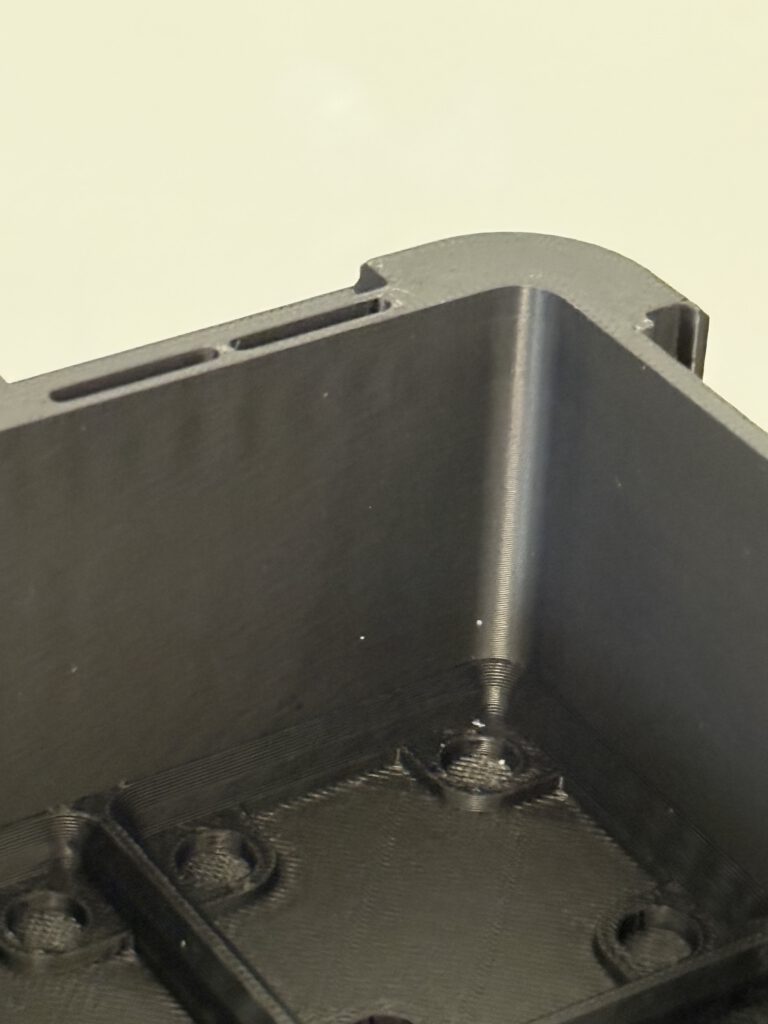

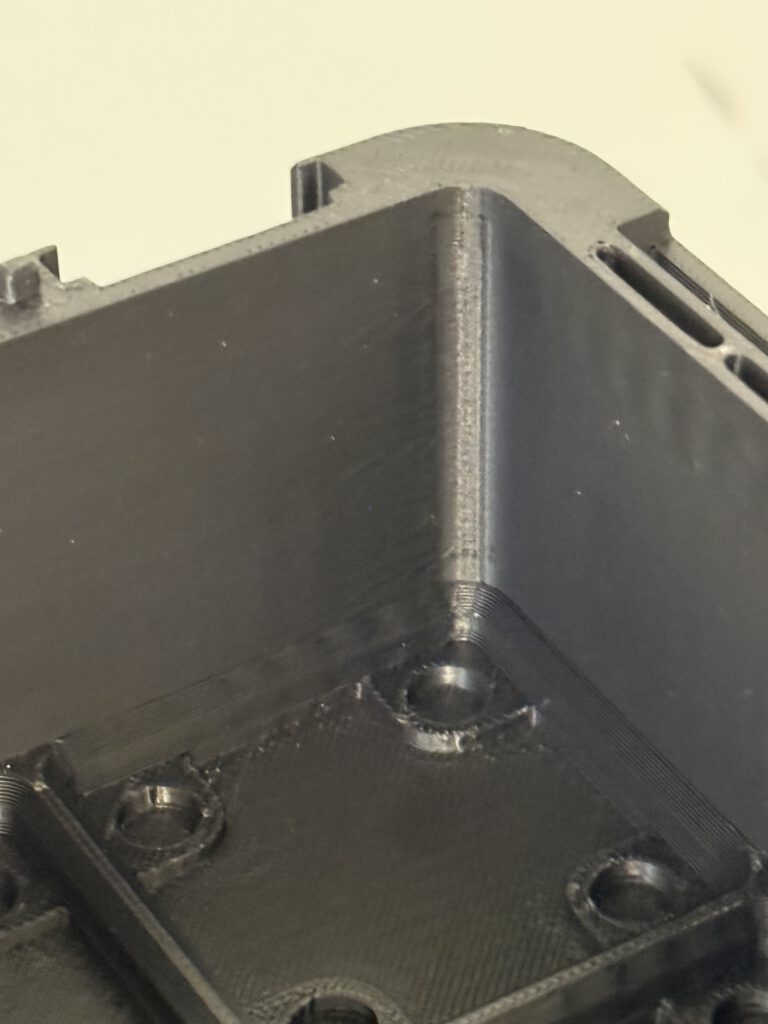

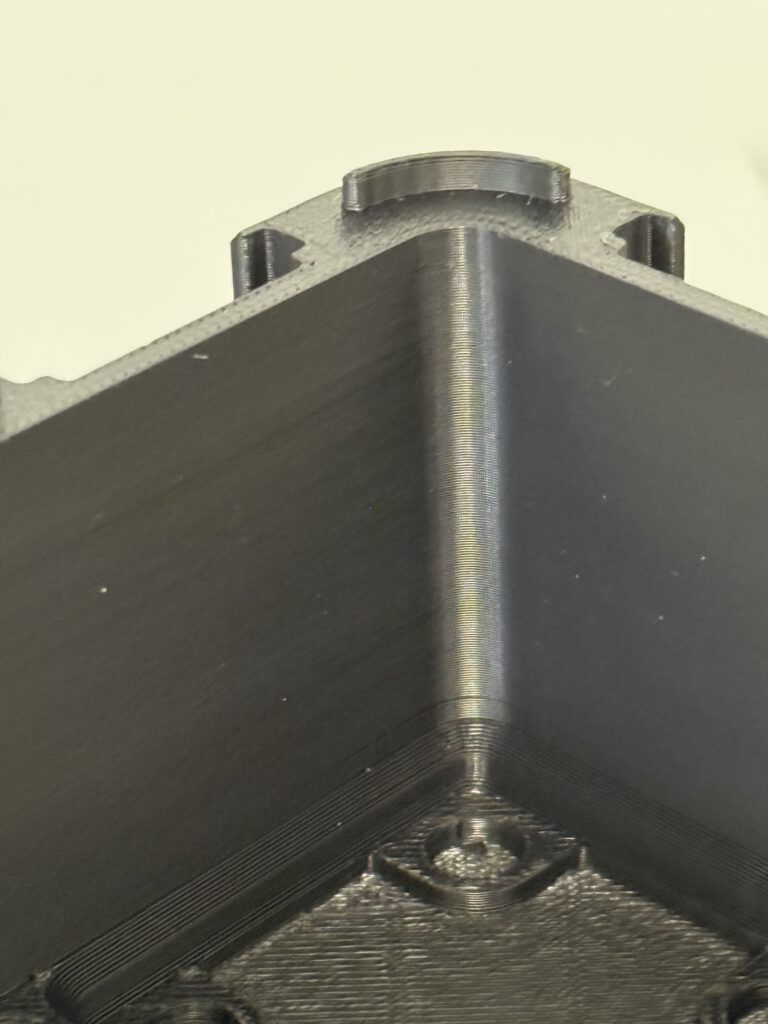

Gridfinity box

This is a model designed by @Pred on Printables. I printed this mostly for keeping all the screws in place when I am going to build the Voron. I included this print to showcase the adaptive pressure advance that I tuned so the corners are smooth. VFA is still something I’m tackling with but I believe it could be due to the stepper motors and will need other macros to tune it out.

More about me

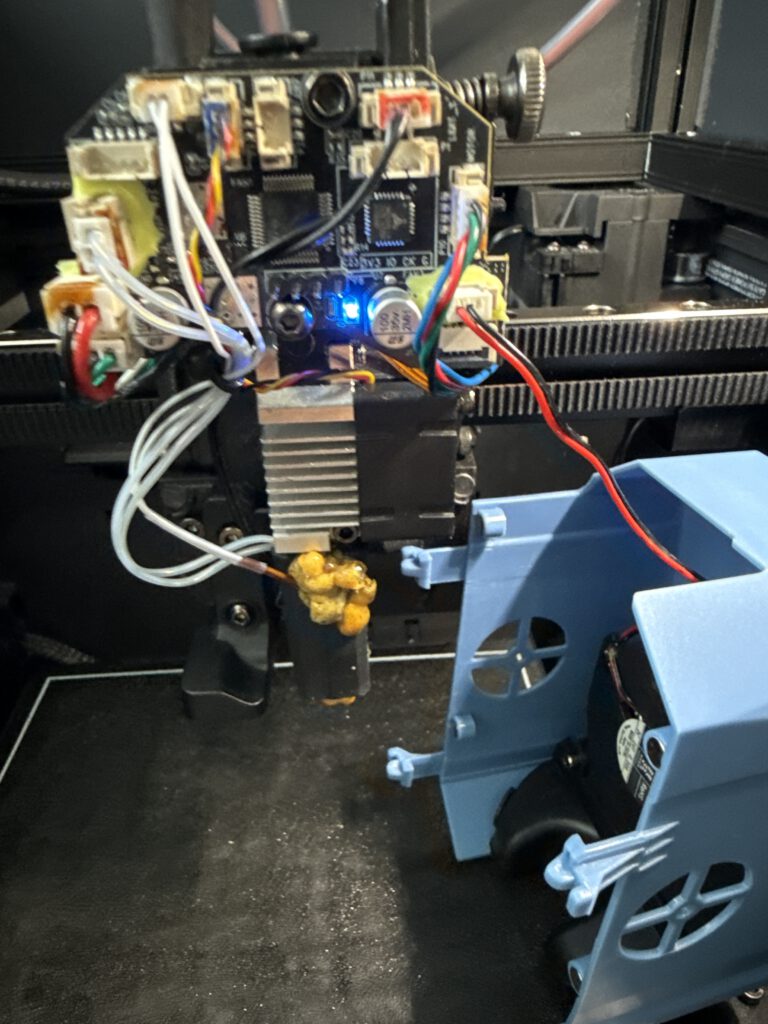

A few hours before I typed this out, I pushed the max volumetric flow rate too far for PLA and basically broke the hotend. I believe that although I am not chest deep in the hobby just yet, my passion for creating a smooth surface finish to every print will be an asset to Pantheon Design.

Other than that, I want to let you know that I am fluent in Cantonese, Mandarin and English. I worked with an earphone factory as a liaison to facilitate a product launch from inception to the demo phase. I also have a background in web programming in PHP, so I know I can write custom macros down the line as well. I have also tried working on an ESP32 project to create a wifi-enabled volume control for my HiFi system in Python.

I look forward to meeting the team and having a chat about begg printers, and getting to know you all. I would really like to move my life and career more towards what Pantheon Design is doing. Thanks.